Arresting cables on aircraft carriers are simple devices but play an extremely important role in helping aircraft land and land safely in the parking area. According to information, only the US, Russia and China can produce this type of cable.

This type of cable must use a special type of steel, which has very high hardness and abrasion resistance, so the production cost is up to more than 1.3 million USD (equivalent to more than 34 billion VND).

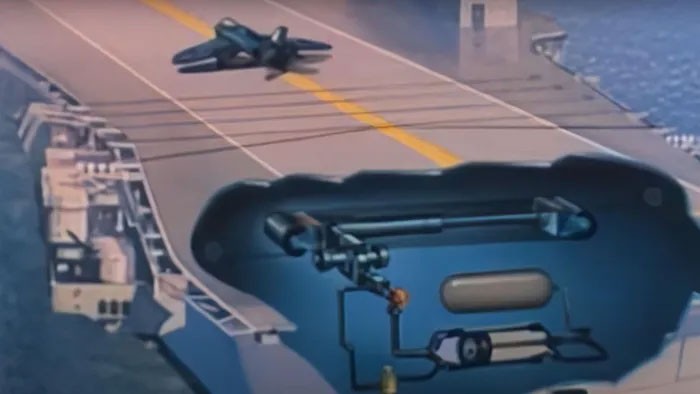

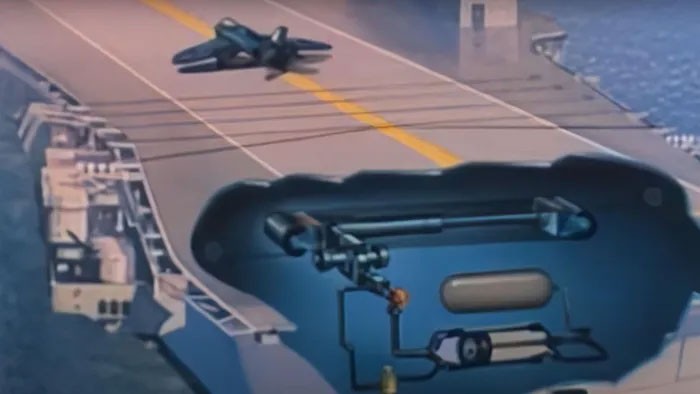

The cable is braided from many small steel cables, around a synthetic fiber cable core, which can withstand a maximum tensile force equivalent to 92 tons. It is stretched 25-36m across the runway, while the two ends of the cable are connected to other cables under the deck with a length of up to nearly 400m, with a maximum tensile force of nearly 100 tons.

This cable system takes only 2 seconds to stop a 22-ton aircraft flying at 240 km/h with a stopping distance of only 105 m. And the process of parking the aircraft, re-tensioning the cable to prepare for the next landing takes only 45 seconds.

The arresting cables and towing cable system must be carefully checked and the cable tension adjusted after each landing of each aircraft.

After about 125 braking operations, the cables will be replaced, while the life of the under-deck cables can be up to 1,400 braking operations.

When the plane lands, this cable will pull a piston that moves along the oil-filled cylinder to absorb the energy of the plane when landing. Depending on the weight of the plane, the amount of oil is adjusted accordingly. When the piston moves 1 m, the cable will release 18 m.